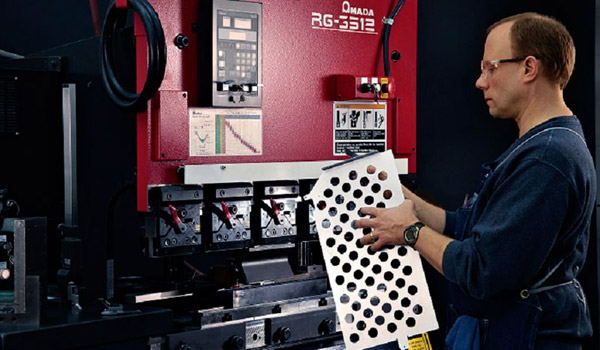

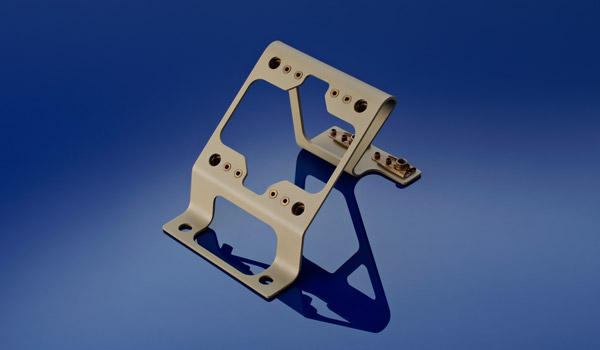

With our diverse range of capabilities, CFW Precision Metal Components is an expert provider of sheet metal fabrications. From projects that involve making a few simple bends in a blanked metal pattern to those with complex welding and structural requirements, we have the skills and equipment to fulfill your needs. Our facility houses all of the different types of equipment that you would expect to see on the floor of an experienced fabrication shop. In addition to press brakes, turret presses, and bending machinery, we are outfitted with high-powered shears, forming presses, piercing machinery, spot and resistance welding equipment, and much more.

With bending capacity of 39.0”, we specialize in producing smaller-sized metal fabrications from sheet materials measuring up to .188” in thickness. Using both CNC controlled and manually guided fabrication equipment, we process all types of metal, including architectural grades, heat resistant alloys, perforated sheet, and many others. Our production resources allow us to fabricate close-tolerance workpieces that meet the high standards of quality required by the electronics, aerospace, military, marine, and commercial industries. We have a strong background using sheet metal fabrication for prototype development. The versatility of our sheet metal fabrication capabilities expedites the production of sample parts so that the design, form, fit, function, and manufacturability can be tested, analyzed, and verified. We focus on understanding your product application, cost constraints, quality objectives, and any other aspects of concern so we can provide you with exactly what you need within your budgetary guidelines.

For more detailed information about our ISO 9001 certified sheet metal fabrication services or to obtain a quote, Contact us today.

SHEET METAL FABRICATION SPECIFICATIONS

- Fabrication Process

Bending

Folding

Forming

Shearing

- Automation Capabilities

CNC

Manual

- Materials

Aluminum

Architectural Metal

Brass

Bronze

Carbon Steel

Copper

Heat Resistant Metals

High Temperature Alloy

Iron

Nickel

Nickel Alloy

Perforated Metal

Stainless Steel

Steel

- Raw Material Forms

Sheet

- Sheet Metal Dimensions

Thickness: .188”

Bend Length: 39”

- Tolerance (+/-)

.005”

- Production Volume

Prototype Medium Volume (5,000+ Parts)

- Lead Times Available

Standard 35 Days

Quoted on job by job basis

Emergency services available (AOG)

AOG 24 Hour Turnaround

ADDITIONAL INFORMATION

- Industry Focus

Aerospace

Commercial

Electronic

Marine

Military

- Industry Standards

ISO 9001

International Organization for Standardization

- File Formats

AutoCAD (DWG,DWZ)

BMP

Bit Mapped Graphics

Catia (CATDrawing,CATPart)

DXF

Drawing Interchange Format, or Drawing Exchange Format

IGES

Initial Graphics Exchange Specification, ANSI file format.

Inventor (IDW, IPT)

JPG or JEPG

Joint Photographic Experts Group

MasterCam (MDX, MC8, MC9, SET)

PDES

Product Data Exchange using STEP, Standard for the Exchange of Product Model Data. A standard format for exchanging data between advanced CAD and CAM programs.

PDF

Portable Document Format

Pro-E or Pro/Engineer (DRW,PRT,XPR)

SAT

3D ACIS Model File

SolidEdge (DFT)

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

STEP

Standard for the Exchange of Product Model Data